The preheating requirements for aluminum castings and the proper use of aluminum casting molds.

Release time:

2024-12-23

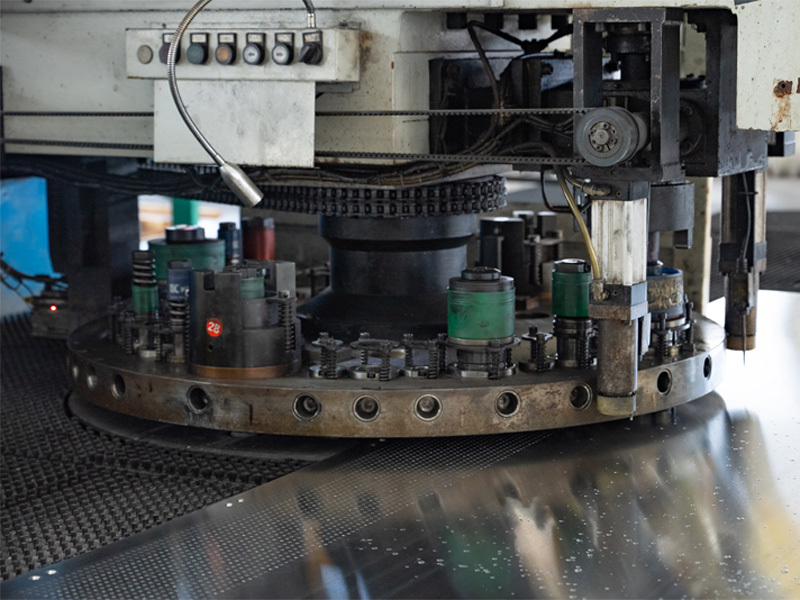

Aluminum castings need to be preheated before use. Aluminum molds must be preheated to a certain temperature before use. Preheating can extend the lifespan of the molds.

Aluminum castings need to be preheated before use. Aluminum molds must be preheated to a certain temperature before use. Preheating can extend the lifespan of the mold. Typically, preheating is done using electrical appliances or induction heating. The preheating temperature is controlled between 250℃ and 300℃. It can be used after maintaining the temperature for about 0.5 hours. It is prohibited to preheat the mold directly with molten metal, as the cold mold coming into direct contact with hot liquid metal will inevitably suffer thermal shock, leading to thermal corrosion and accelerating cracking and peeling caused by thermal fatigue.

In the process of manufacturing aluminum castings, the surface treatment quality of the mold cavity can be effectively improved. The surface of the mold cavity should not have obvious deep processing tool marks to prevent cracking due to stress concentration during the precision machining of the mold. The surface of the cavity should be effectively polished and ground, controlling the surface roughness to below 0.8μm.

In continuous production, the temperature of aluminum casting molds tends to rise. Excessively high temperatures not only cause the liquid metal to produce large clumps but also slow down the cooling rate of the casting, leading to coarse grains and reduced quality of the aluminum casting. Therefore, when the temperature of the aluminum casting mold is too high, cooling measures should be taken. Compressed air or water is usually used for cooling. Aluminum casting molds are typically designed with cooling systems to ensure thermal balance of the mold.

After using aluminum casting molds, the mold cavity should be cleaned in a timely manner to effectively remove residual aluminum. After cooling, rust prevention treatment should be carried out, and the molds should be stored in a warehouse for centralized management for future use. At the same time, by managing the design, manufacturing, use, maintenance, and management of the molds, the lifespan of aluminum casting molds can be effectively extended, thereby reducing motor manufacturing costs.

Key words:

Learn more dynamic

Higher product quality, faster shipping cycle, lower sales price, and a wider range of specifications and models.

Professional aluminum processing enterprise

Service Hotline

Mailbox:75749189@qq.com

Address:Industrial Zone, Yuetan Town, Luoyang City, Henan Province

Amy Metal

Website construction: 300.cn | SEO Business card

Support IPV4/IPV6 bidirectional access

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSAZE-ZXA

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page