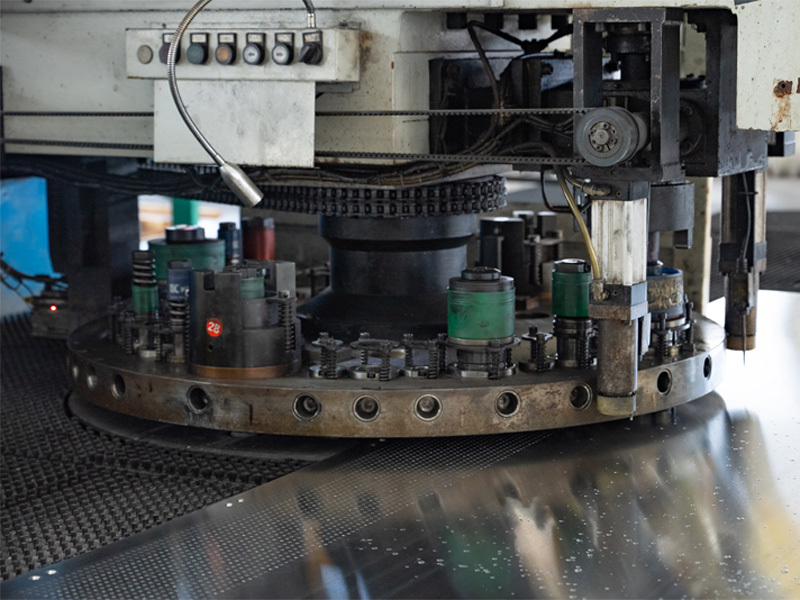

What are the commonly used aluminum alloy plates on machine tools?

Release time:

2024-12-28

Aluminum-magnesium alloy materials can meet the requirements of machine tools for the strength, hardness, corrosion resistance, and forming performance of aluminum alloys.

The commonly used aluminum alloy plates on machine tools are mainly 5-series and 6-series aluminum alloys, made of aluminum-magnesium alloy material, which can meet the requirements of machine tools for aluminum alloy strength, hardness, corrosion resistance, thermal stability, and forming performance. The popular machine tool aluminum alloy plate products from Henan Mingtai Aluminum mainly include 6061 aluminum plate and 5083 aluminum plate.

Advantages of aluminum alloy machine tool performance

Aluminum alloys have high strength and hardness, which can meet the stability requirements of machine tools during high-speed operation and heavy load.

Aluminum alloys have good corrosion resistance, which can resist corrosive media in the working environment and extend the service life of machine tools. This can reduce performance degradation and maintenance costs caused by corrosion.

Aluminum alloys can maintain stable performance in high-temperature environments, avoiding precision degradation of machine tools due to thermal expansion or thermal stress.

6061 Aluminum Plate:

Characteristics: 6061 aluminum plate is a commonly used aluminum alloy material with moderate strength and easy processing. It has good formability, weldability, and machinability, while maintaining medium strength. It can still maintain good operability after annealing, making it very suitable for machine tool processing.

Applications: Widely used in aerospace, automotive manufacturing, mold manufacturing, electronic product component processing, and other fields. On machine tools, it is commonly used for processing various complex components, such as automotive parts, bicycle frames, computer parts, etc.

5083 Aluminum Plate:

Characteristics: 5083 aluminum plate is a high-strength aluminum alloy material with good corrosion resistance and weldability. Its strength and corrosion resistance are outstanding, making it suitable for use in humid or corrosive environments.

Applications: Widely used in shipbuilding, marine engineering, automotive body manufacturing, mold manufacturing, electronic product component processing, and other fields. On machine tools, it is commonly used for processing parts that need to withstand certain stress and corrosive environments.

In addition to the commonly used aluminum alloy plates mentioned above, other types of aluminum alloy plates, such as 5052 aluminum plates, may also be used on machine tools depending on specific processing needs and application scenarios. These aluminum alloy plates each have their unique properties and characteristics, and choosing the right aluminum alloy plate is important for improving processing efficiency and ensuring product quality.

Key words:

Learn more dynamic

Higher product quality, faster shipping cycle, lower sales price, and a wider range of specifications and models.

Professional aluminum processing enterprise

Service Hotline

Mailbox:75749189@qq.com

Address:Industrial Zone, Yuetan Town, Luoyang City, Henan Province

Amy Metal

Website construction: 300.cn | SEO Business card

Support IPV4/IPV6 bidirectional access

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSAZE-ZXA

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page